How does a rotary evaporator

work and what are its uses?

How does a rotary evaporator work and what are its uses?

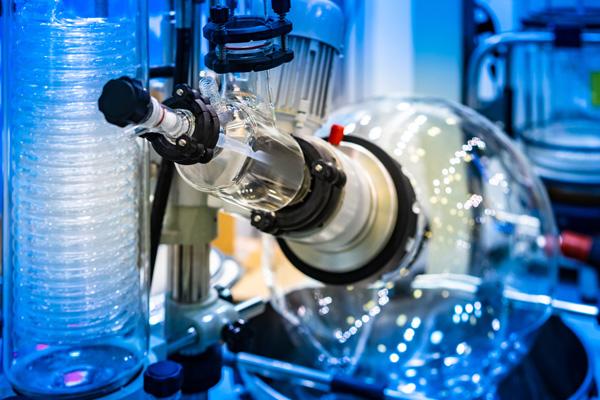

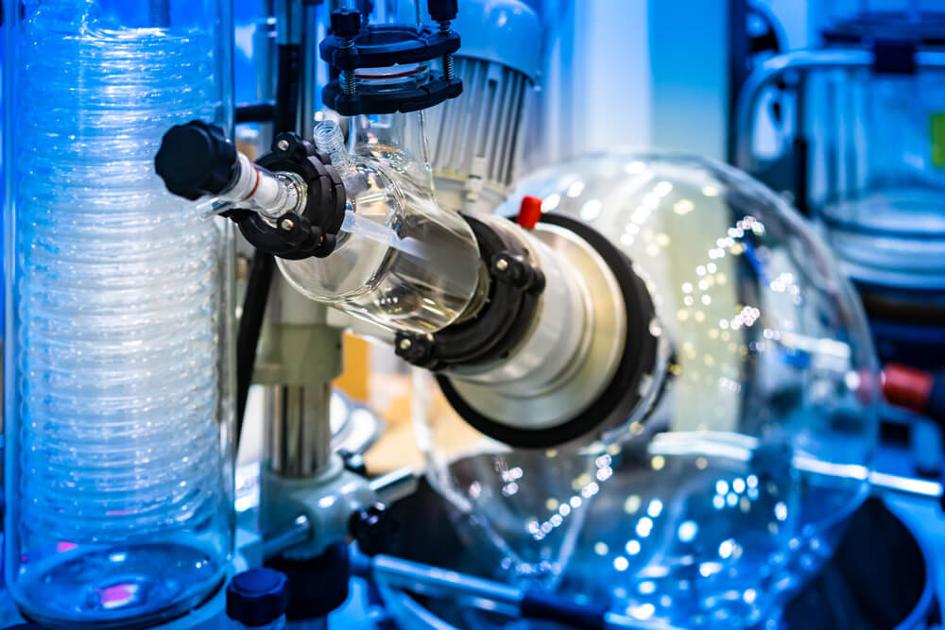

What is a rotary evaporator?

A rotary evaporator is an essential laboratory tool used for evaporation, distillation, and solvent recovery. It separates and concentrates solvents from chemical solutions through gentle evaporation under reduced pressure. The rotary evaporator consists of a rotating flask immersed in a heated water bath, connected to a vacuum pump.

As the flask rotates, the solvent undergoes an evaporation process at a lower temperature than its boiling point, making it ideal for sensitive compounds. This method ensures solvent removal without compromising quality. Rotary evaporators are crucial for a wide range of applications, including purification, sample preparation, and concentration, in chemistry, pharmaceuticals, and other scientific fields, enabling opportunities for efficient and precise solvent management.

How does a rotary evaporator work?

A rotary evaporator efficiently removes solvents from liquid mixtures under controlled conditions. It reduces pressure and heating to facilitate the solvents’ rate of evaporation while minimising the risk of heat-induced damage in sensitive samples. Here is a quick guide to how it works:

- Flask: The evaporation process begins with a round-bottom flask containing the liquid mixture to be concentrated. This flask is typically placed in a heating bath to provide consistent and gentle heating.

- Rotation: As the flask is attached to a rotating mechanism, the motion of it continuously agitates the liquid. This increases the surface area exposed to the heated water bath, promoting an even and efficient evaporation.

- Vacuum System: A vacuum pump is connected to the system, which reduces pressure inside the flask and lowers the boiling points of the solvents. This allows the removal of solvents at much lower temperatures than at normal atmospheric pressure.

- Cooling System: A condenser or cooling coil is positioned above the flask to collect and condense the evaporated solvent vapours. This condenser cools the vapour back into a liquid form, which can be collected separately.

- Collection Flask: When the evaporation process is complete, the condensed solvent is then collected in a separate container known as the receiving flask.

By combining controlled heating, vacuum pressure, and continuous rotation, the rotary evaporator can effectively separate solvents from the desired compounds in a sample.

What are the parts of a rotary evaporator?

1.Rotary motor

A rotary motor is a key component of the rotary evaporator. It is responsible for turning the round-bottomed flask, and ensuring that heat is evenly distributed for efficient solvent evaporation.

2.Vacuum source

A vacuum source in a rotary evaporator is also known as a vacuum pump. It reduces pressure inside the system, lowering the boiling points of solvents. It facilitates solvent evaporation at lower temperatures to ensure quality control of the separation and concentration of samples in the rotary evaporator.

3.Glass tube

The glass tube contributes to the condensation system. It functions as a cooling component, whether in the form of a cooling coil or a condenser, which is responsible for condensing solvent vapours back into a liquid phase, enabling the separation and collection of the concentrated solvent.

4.Heating bath

A heating bath is a water or oil-filled container beneath the round-bottomed flask. This provides uniform and controlled heating to the sample. Because of its ability to control heating temperatures, it can accelerate the evaporation process by raising temperatures without direct exposure to high heat, reducing the risk of sample degradation.

5.Condenser

A condenser in a rotary evaporator is responsible for cooling and condensing solvent vapours generated during the evaporation process. It converts the vapour back into a liquid state, facilitating the separation and collection of samples while preventing solvent loss and enabling efficient solvent recovery.

6.Receiving flask

A receiving flask is a container used to collect the concentrated sample after solvent removal. It allows for the separation of the concentrated material from the remaining solvent, enabling precise control and retrieval of the end product.

Types of Rotary Evaporators and Their Applications:

2L Rotary Evaporator

A 2L rotary evaporator is a laboratory instrument designed for solvent separation and concentration in small-scale applications. It efficiently removes solvents from liquid samples under reduced pressure and controlled temperature. It consists of a 2-litre flask and a motorised rotating mechanism.

See the 2L SolventVap Rotary Evaporators

The Across International 2L SolventVap rotary evaporators are an ideal choice for benchtop evaporation and solvent recovery. They feature high distillation rates and an economic footprint, as well as a modular heating bath and digital temperature/rotation control. These efficient 2L rotary evaporators come in two configurations; one with a standard cooling coil condenser, the other with a Dewar style condenser, able to hold dry ice and various cooling media. All Ai SolventVap rotary evaporators are UL/CSA certified and carry a comprehensive 1-year warranty.

5L Rotary Evaporator

A 5L rotary evaporator is designed for solvent evaporation and concentration on a larger scale. This comprises a 5-litre flask and a motorised rotating system. Its purpose is to efficiently remove solvents from liquid samples under reduced pressure and controlled heating, facilitating the purification and concentration of chemical compounds in various scientific applications.

See the 5L SolventVap Rotary Evaporators

Across International 5L SolventVap rotary evaporators provide a powerful platform for evaporation and solvent recovery, they feature high distillation rates and an economic footprint. These powerful 5L rotary evaporators come in two configurations; one with a standard cooling coil condenser, the other with a Dewar style condenser, able to hold dry ice and various cooling media. All Ai SolventVap rotary evaporators are UL/CSA certified and carry a comprehensive 1-year warranty.

10L Rotary Evaporator

A 10L rotary evaporator consists of a 10-litre flask and a rotating system designed to effectively evaporate solvents on a larger scale. This involves the same process of reduced pressure and controlled temperature, facilitating the purification and concentration of chemical compounds which is applicable to diverse applications in the fields of pharmaceuticals, chemistry, research and more.

See the 10L SolventVap Rotary Evaporators

Browse our selection of 10L rotary evaporators, turnkey packages, and accessories. Ai SolventVap 10L rotary evaporators are ideal for a wide range of applications providing powerful distillation, with ease of operation. All Ai SolventVap rotary evaporators come standard with UL/CSA certification and carry a comprehensive 1-year warranty. For efficient and powerful distillation, there is no better solution than an Ai SolventVap system.

20L Rotary Evaporator

A 20L rotary evaporator is used for solvent removal and concentration in larger volumes using a 20-litre flask and a motorised rotation system. Under reduced pressure and controlled heating, it enables the purification and concentration of chemical compounds.

See the 20L SolventVap Rotary Evaporators

Ai 20L SolventVap rotary evaporators feature locking swivel casters, on all four legs, making repositioning and moving a breeze. In addition to ease of operation, our systems also provide key safety features like dry run protection, over-temp shut offs, and built-in circuit breakers, to ensure safe and reliable performance. Ai 20L rotary evaporators are built to provide powerful and efficient evaporation across numerous applications.

50L Rotary Evaporator

A 50L rotary evaporator is designed for solvent removal and concentration on a significant scale. With its 50-litre flask and motorised rotating mechanism, it facilitates efficient evaporation of solvents and enables the purification and concentration of chemical compounds.

See the 50L SolventVap Rotary Evaporators

Across International 50L SolventVap rotary evaporators provide a powerful platform for evaporation and solvent recovery. Our production-scale SolventVap 50L rotary evaporators feature locking swivel casters, on all four legs, making repositioning and moving a breeze. In addition to ease of operation, our systems also provide key safety features like dry run protection, over-temp shut offs, and built-in circuit breakers, to ensure safe and reliable performance.

How to Set Up a Rotary Evaporator?

Proper setup and careful monitoring are essential for a safe and effective outcome using the rotary evaporator. Setting up a rotary evaporator involves several steps:

- Assemble: Place the rotary evaporator on a stable, level surface. Assemble the glassware components, including the round-bottomed flask, condenser, and receiving flask, ensuring each is connected properly and tightly sealed.

- Turn the Power On: Connect the unit to a power source and switch it on.

- Cooling: Start the cooling system, usually a water bath and set it to the desired temperature for the condenser.

- Vacuum Pump: Connect the vacuum pump to the system and use the vacuum valve to start your vacuum process.

- Sample: Place the sample in the round-bottomed flask and secure it.

- Rotation: Start the flask rotation to enhance solvent evaporation.

- Heating: Gradually heat the water bath to the desired temperature for solvent evaporation.

- Monitoring: Monitor the process to ensure optimal solvent removal and prevent sudden boiling.

- Collection: Collect the condensed solvent in the receiving flask.

- Shutdown: Once the process is complete, turn off all your equipment such as the heating bath, vacuum pump, and cooling system. Carefully disconnect and disassemble the glassware.

What Industries Use a Rotary Evaporator?

Rotary evaporators are versatile tools used across various industries. Here are a few examples in where their function is essential:

Chemical and Pharmaceutical Sectors

Rotary evaporators aid in solvent removal, compound purification, and concentration.

Food and Beverage Industry

Because of its process to separate materials, rotary evaporators assist in flavour extraction and concentration.

Environmental Analysis

Laboratories use these to analyse pollutants. They are crucial in research and development for academia and industrial research, such as in the development of new materials.

Additionally, they're used in essential oil production, petrochemical research, and many other fields where precise solvent separation and concentration are essential for product development and analysis.

Main Applications of a Rotary Evaporator:

Extraction

The extraction process requires a liquid mixture to be placed in a round-bottomed flask and rotated while subjected to reduced pressure. The solvent evaporates at a lower temperature and separates the desired compounds. The condenser then extracts the solvent vapour for collecting while the concentrated sample remains in the flask.

Distillation

When a liquid mixture is heated in a round-bottomed flask and a vacuum is applied, the solvent evaporates at a lower temperature from the reduced pressure. This enables the target compounds with higher boiling points to remain. The condensed solvent vapour is then collected separately.

Solvent Recovery

Solvent recovery involves the process of evaporating solvents from a solution under reduced pressure and controlled heating. The solvent vapours are then condensed, converting back into liquid form. This enables the separation and collection of the recovered solvent while leaving the concentrated sample behind.