1. Features and main uses of the equipment

Basic principle and application: The equipment is applicable for non-polluting heat treatment of materials under vacuum or atmosphere protection. Can be sintered in nitrogen, argon, hydrogen, and other atmospheres. Mainly used in high temperature atmosphere sintering, high temperature vacuum sintering, transparent ceramics, and other materials sintering.

2. Structural composition

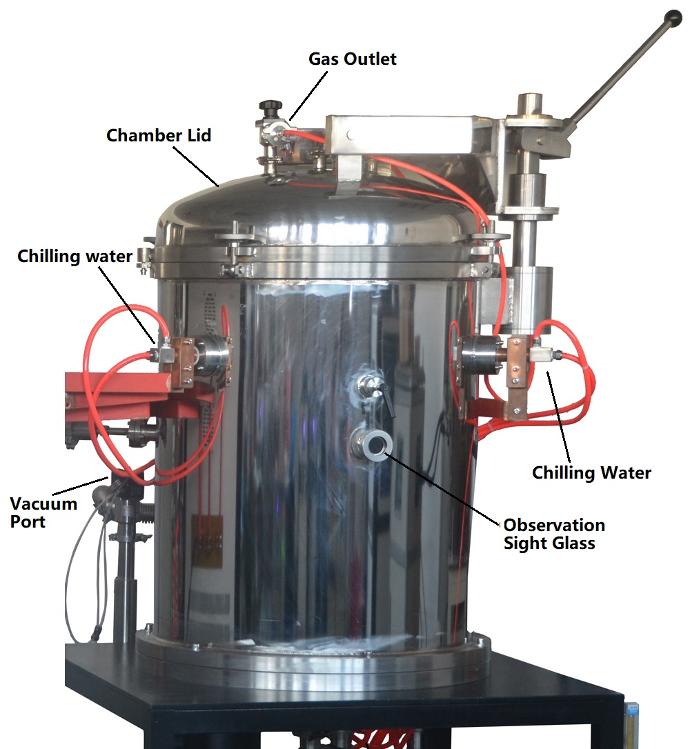

Furnace body, furnace cover, furnace bottom, vacuum system, control system, cooling system, heating element and heat shield, etc.

3. Structure description

1. Furnace body: It is a vertical furnace shell, the inner and outer layers are made of 304 stainless steel cylinders, and the outer layer is mirror polished. The inner and outer cylinders, the front and rear flanges are welded into a whole. The furnace body is provided with connections ports like electrode connection, air extraction, air release inlets and outlets, thermocouple port, infrared port and observation sight Glass etc. The material of each interface is stainless steel.

2. Furnace cover: is welded by inner and outer heads and flanges. The middle can be cooled by water. The furnace cover can be opened.

3. Furnace bottom: It is composed of inner head, outer head and flanges. The middle is cooled by water. The lower part is provided with a charging and venting port, which is fixed at the lower part of the furnace body and is provided with an electrode lead-out device.

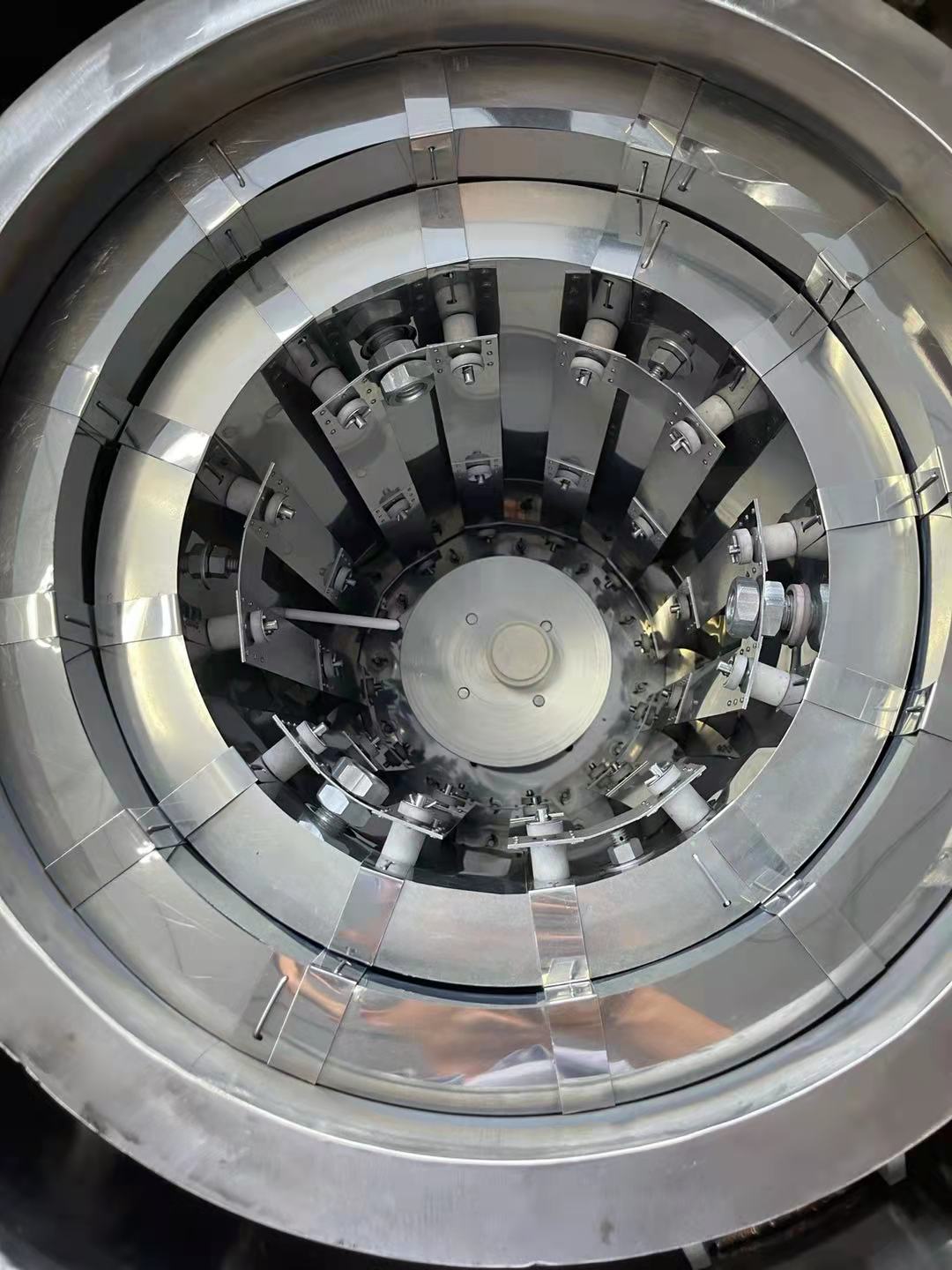

6. Heating body and heat shield: The innermost layer of the heat shield is made of tungsten plate, and the outer layer is made of stainless-steel plate.

7. Vacuum system: It is composed of direct-connected pump , molecular pump or diffusion pump, pneumatic flapper valve, pneumatic shut-off valve, digital display composite vacuum gauge, vacuum pipeline, air release valve, bracket, etc.; Metal corrugated hose quick connector connection (slow vibration).