Across

International IHE series induction heaters are designed with mid working

frequency between 30 and 100 KHz. Mid frequency hand-held induction heating

machine is the newest hand-held heating model. It is excellent for copper pipe

welding due to the design of its 3-5 meters extended handheld heating head and

fast heating rate.

Among all types of induction heaters, mid frequency induction heaters are the

simplest in term of design with the low maintenance, and are the most popular,

affordable and reliable machines, especially between 15kw and 25kw models. The

large capacity and small size at an affordable price make these models the

standard equipment for a lot of factories, labs and workshops.

Main Features

·

Ease of use: just connect the power and the

water cooling system. Our simple instruction allows you to use the heater in 15

minutes.

·

3-5 meters extended handheld heating head

with power switch.

·

Precise control with digital time and current

displays.

·

Remote foot switch for safer operation.

·

Dual automatic and manual modes.

·

Optional graphite, MgO and SiO2 crucibles available. (melting material decides crucible type,

weight and size of the material decide crucible size)

·

Custom coil design available (fixed coil or coil on a cable

so it can be used by hand like a wand)

Indicators

·

Power

indicator:

When input power

is connected, circuit breaker in back panel and main power switch in the front

are turned on, this red light is on indicate the control power is OK.

·

Operation

indicator

This green light

will flash with intermittent buzzing sound (around one in each second) during

heating process.

·

Output

over voltage indicator

NULL

·

Water

fail indicator

The induction coil and some parts inside

the machine are all cooled by cooling water. This machine comes with a built-in

water pressure sensor. If cooling water pressure is lower than the rated value,

this light will turn on with continuous buzzing sound, and the machine will

stop working automatically.

·

Phase

protection indicator

Control power is

drawn from two of the phases of a three-phase power. Two situations: A) One of

the control power phases is missing. Machine will not work and power indicator

is off. B) The phase other than the control power phases is missing, phase

protection indicator will light up, machine shuts down automatically with

buzzing sound.

·

Over

current indicator

When this light

turns on with continuous buzzing sound, machine will stop working

automatically. The followings are the possible causes.

b.

Interference

signal

c.

Equipment

failure

d.

Induction

coil short circuit caused by induction coil touching the work piece

e.

Contact

between induction copper turns

f.

Oven

temperature for some parts inside the unit

g.

Input

power overload capability

Restart the

machine normally should fix the problem. If this light comes up with sound

every time you start the machine, there might be a bad part which needed to be

replaced.

·

Short

circuit indicator

When this light is on and the alarm is issued,

the IGBT module or the auxiliary adjustment part of the voltage regulation part

may be damaged, or the short circuit sensor may be damaged. Please refer to the

fault guide or consult our company for repair.

·

Input

over voltage indicator

Input of 380-415VAC three

phase is required for this machine. When input voltage is higher than 430v,

this light will turn on with continuous buzzing sound, and the machine will

stop working automatically.

·

Over

temperature indicator

There is a heat sensor attached to the heat

radiator inside the machine, when the sensor detects a temperature higher than

55°C, over temperature light will come on with continuous buzzing sound.

Increase cooling water flow rate or lower water temperature could resolve this

issue.

·

Over

temperature indicator

When the

temperature of these devices is higher than 55 °C, the device will stop working,

the overheat indicator turns on with continuous buzzing sound. Increase the

water flow to reduce the temperature of the cooling water to release it.

·

Unit

frequency indicator

This light is on

when the device oscillates at a frequency lower than 30KHZ or higher than

100KHZ. The device will continue to operate, but the output voltage, power,

etc. will automatically attenuate to protect the device from damage. It can be

adjusted by the following methods: (1) If the frequency is too low, the number

of turns of the induction coil can be reduced, or the diameter of the induction

coil can be reduced, (2) If the frequency is too high, the number of turns of

the induction coil can be increased, or the inductance can be increased. The

diameter of the circle to reduce the frequency.

·

Frequency

(KHZ) indicator

This light will come up when the digital gauge

shows the oscillation operating frequency.

·

Current

(A) indicator

This light will come up when the digital gauge

shows output oscillator current.

·

Voltage

(V) indicator

This light will come up

when the digital gauge shows output oscillator voltage.

·

Power

(KW) indicator

This light will come up

when the digital gauge shows output oscillator power.

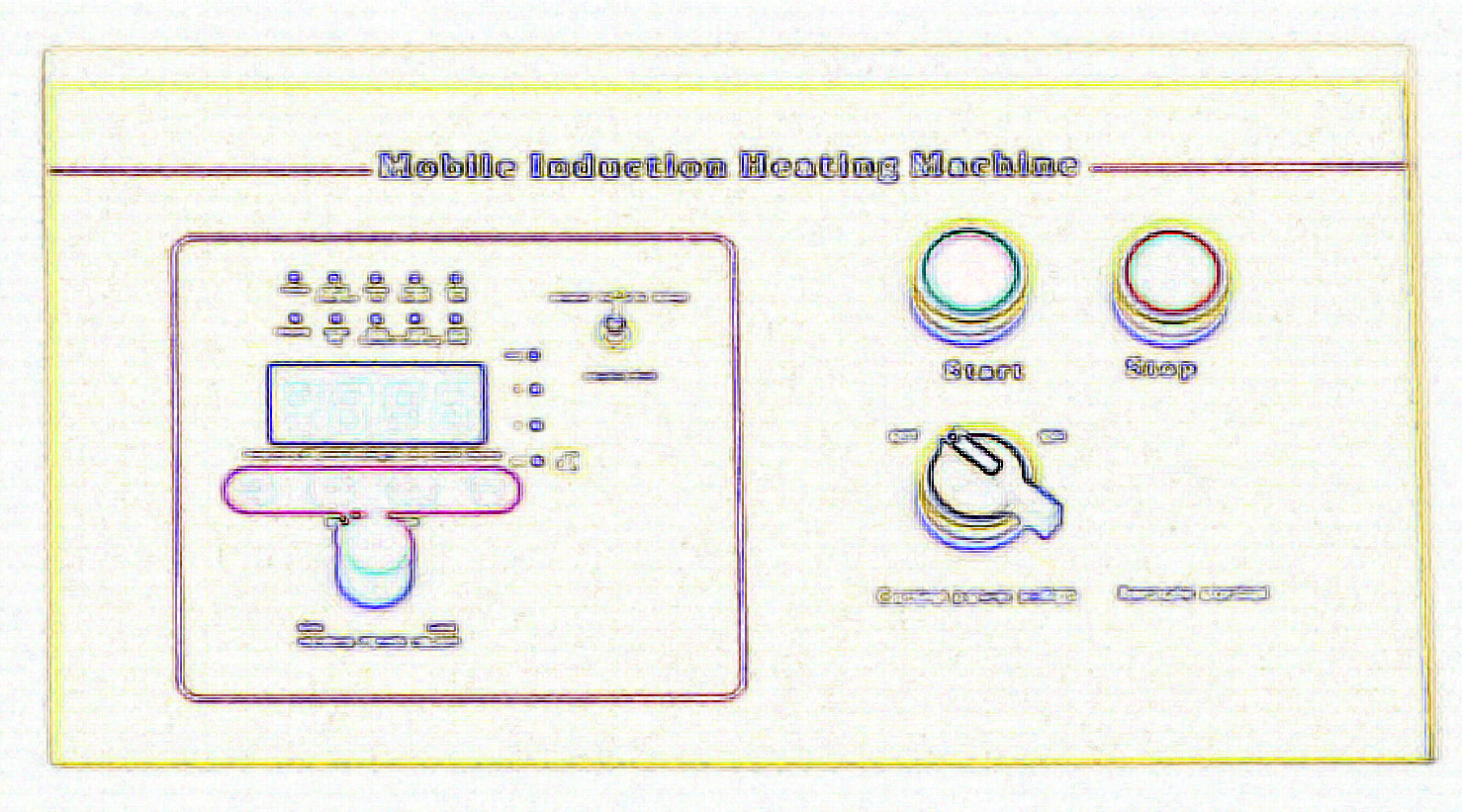

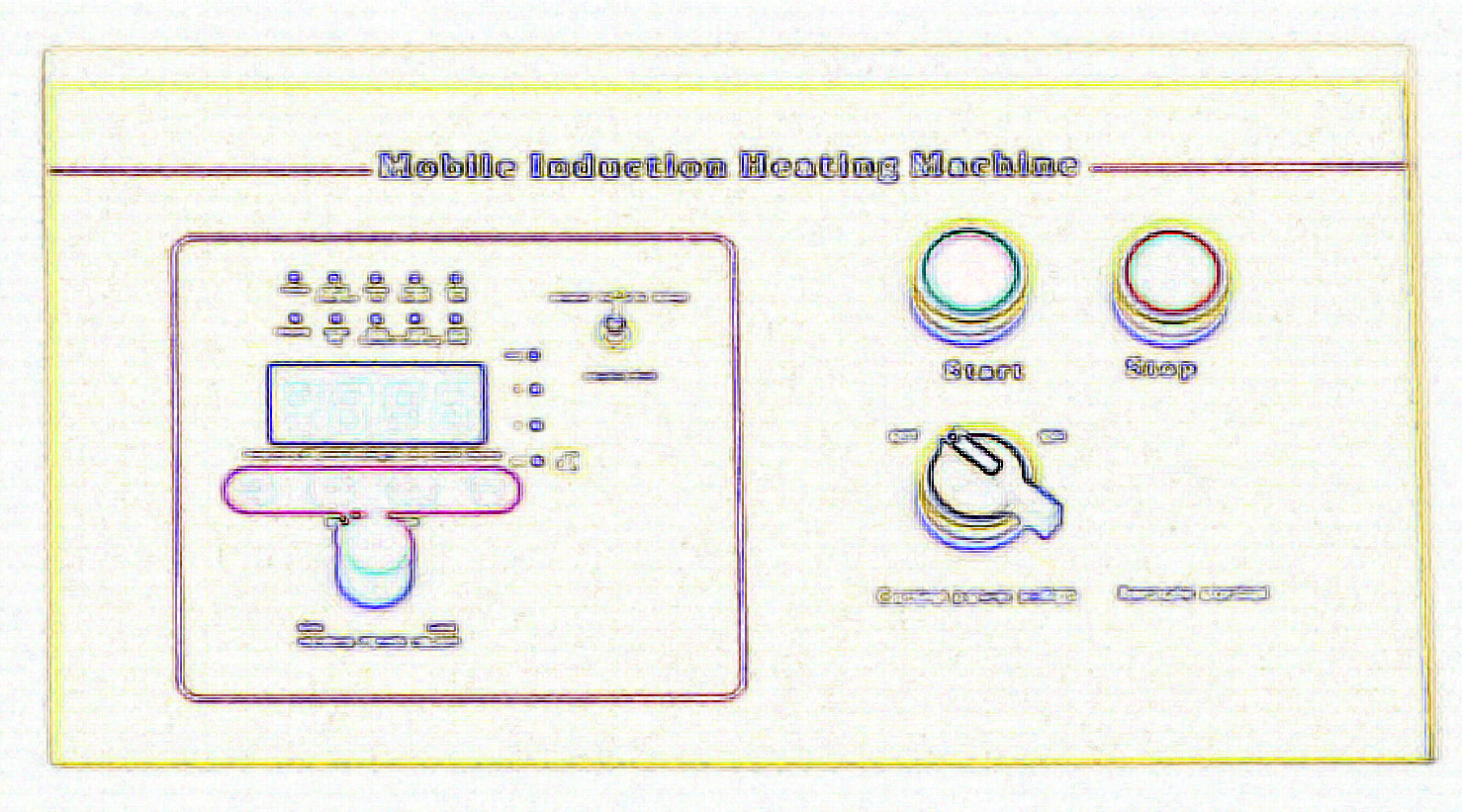

Buttons & Switch

·

Start

button

Press this button once to start heating.

This button is disabled when remote foot switch is connected.

·

Stop

button

Press this button once to stop the heating

process.

·

Frequency

(KHZ) button

Press and hold this button, the digital

display shows the current oscillation frequency (KHZ). The frequency indicator also

will be turned on.

·

Current

(A) button

Press and hold this button, the digital

display shows the output current of the device (A).. The current indicator also

will be turned on.

·

Voltage

(V) button

Press and hold this button, the digital

display shows the current output voltage of the device (A). The voltage

indicator also will be turned on.

·

Power

(KW) button

Press and hold this button, the digital

display shows the current output power of the device (KW). The power indicator also

will be turned on.