This TF1800 series tube furnace is imbued with the highest quality components, providing everything you need to turn out a perfect application time and again. The chamber is made of high-quality 1900 grade alumina fiber insulation. This is surrounded by Sweden’s famous Kanthal 1900 grade molybdenum silicide heating elements. The tremendous heat that’s created is contained by a double-walled steel internal housing. Its Japanese Shimaden 40-segment digital controller is so precise, it can get you within +/- 1°C of your target temperature.

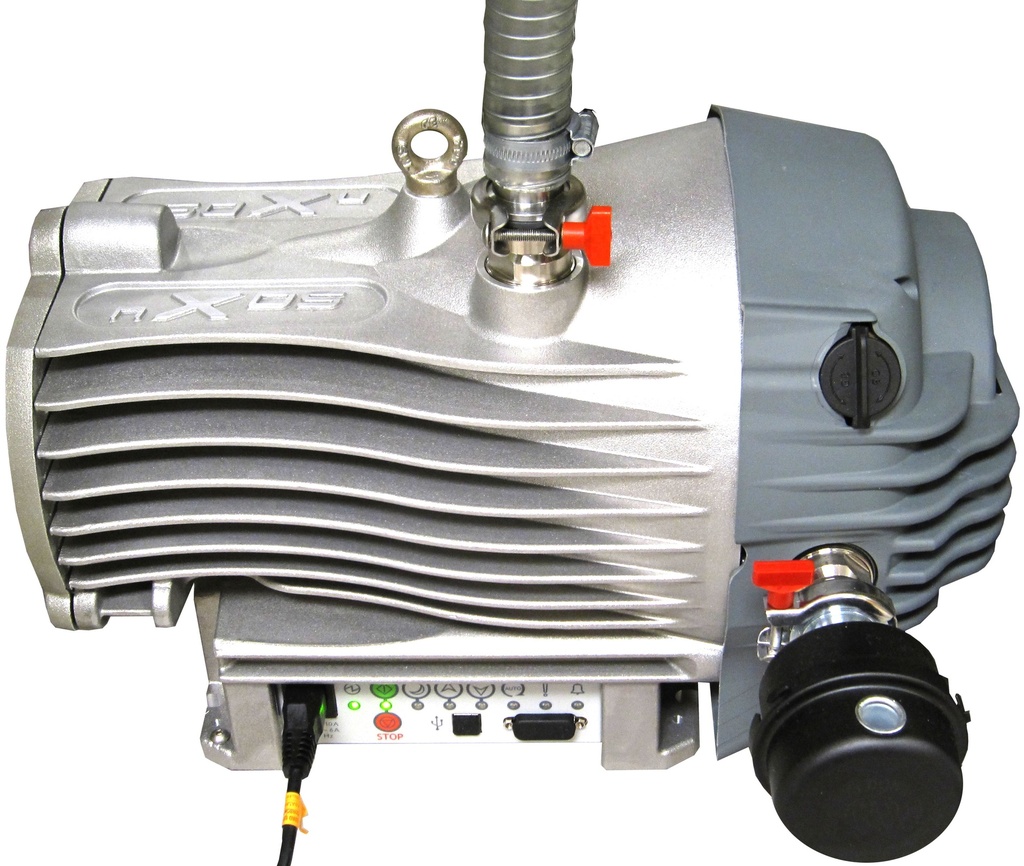

Longevity is ensured by dual sealing flanges--which help preserve the tube, and a type B thermocouple. Its built-in RS485 digital communications port and USB adapter allows for remote control and monitoring straight from your PC. You can even save or export test results. A self-tuning PID control optimize your thermal process while minimizing overshoot.

Built-in ammeter and dual voltmeters provide easy monitoring and troubleshooting. The furnace is lightweight, compact, and portable. It’s also versatile. You can perform multiple atmosphere processes in a single cycle. Safety features include overheat and power failure protection. This as well as all our other furnaces are CE compliant.

Features

- Compact, portable and lightweight design.

- Standard package includes set of stainless steel vacuum sealing flanges with valves and pressure meter.

- Dual flanges support ensures better sealing and longer tube life.

- Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Multiple atmosphere processes in a single cycle are possible (ex: binder burn out in air and parts sintering under rough vacuum or inert gas environment.)

- Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- Long life type B thermocouple.

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

Warning! NEVER fill furnace with explosive gases, including Hydrogen, Carbon Monoxide and Methane.