The Ultimate Guide to Laboratory Grinding Jars

Grinding jars are containers used with a grinding machine or mill to break down solid materials into finer pieces. Made of different materials and offered in a range of sizes, these jars play a pivotal role in various research and industrial applications. Our comprehensive guide delves into the various types and applications of grinding jars. Read below.

What are the different types of grinding jars?

Micro-Scale Jars

Small jars designed for small-scale grinding operations, which are often used in laboratories for research and development purposes.

Standard Jars

Medium-sized jars suitable for general-purpose milling processes in both laboratory and industrial settings.

Large Jars

Used for industrial-scale grinding procedures where large quantities of material need to be processed.

Vacuum Jars

Designed for grinding operations in a controlled environment to prevent reactions with the surrounding atmosphere.

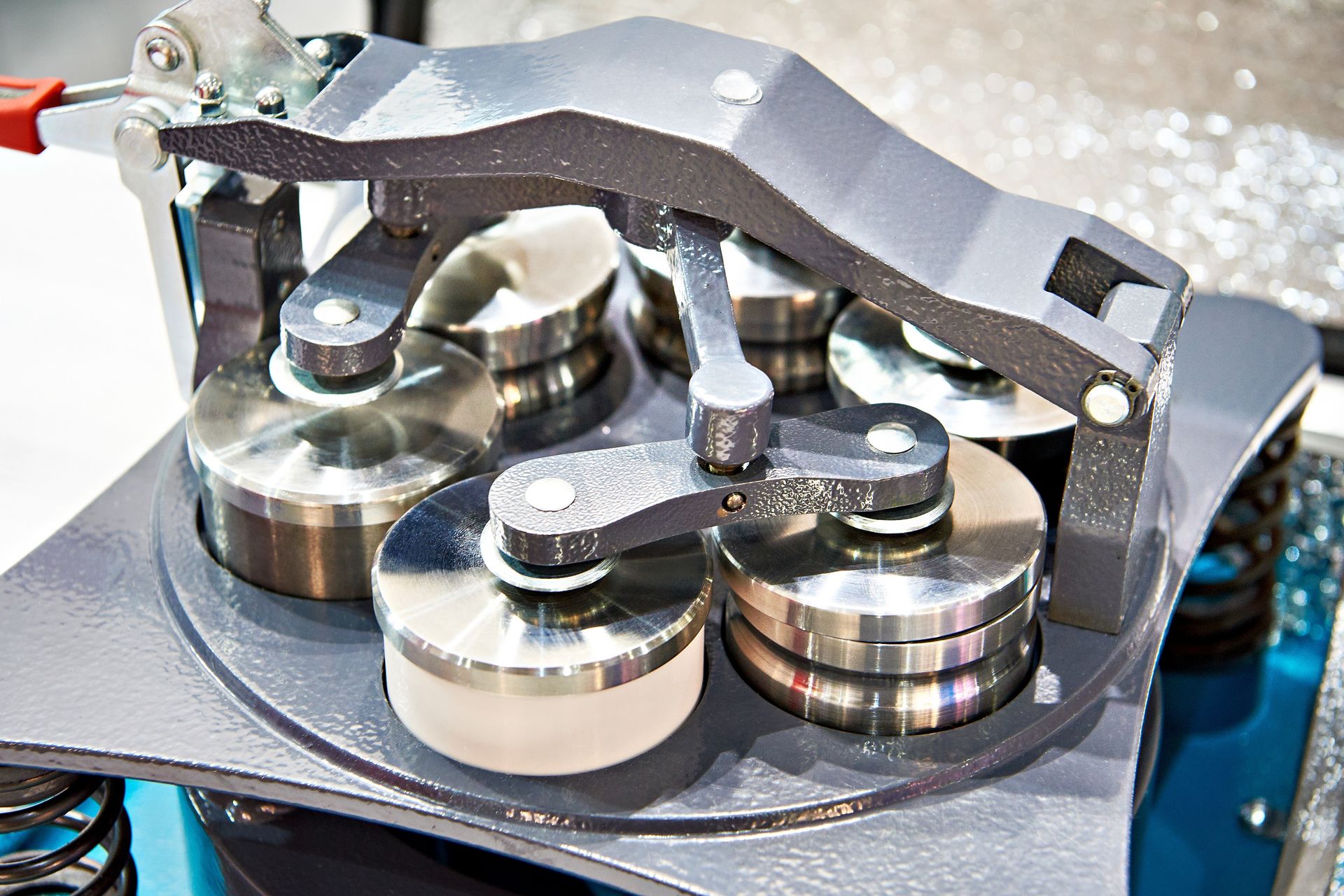

Jars for Planetary Ball Mills

Grinding jars for planetary ball mills are a specialised type of containers designed for ball mills, which is a type of machine that uses metal or ceramic balls as a grinding media.

What are grinding jars made of?

Porcelain Jars

Porcelain jars are chemically inert and resistant to corrosion, which makes them suitable for processing materials that are sensitive to metallic contamination. This type of jar is commonly used in pharmaceutical, food processing, and ceramic industries.

Stainless Steel Jars

Durable and resistant to corrosion, stainless steel jars are renowned for their versatility. They are commonly used for grinding hard materials such as metals, hard alloys, and ceramics.

Nylon Jars

Nylon jars have non-contaminating, non-reactive properties which make them ideal for grinding materials that may be susceptible to contamination. These qualities of nylon jars make them excellent in industries such as pharmaceuticals and food processing where the purity of samples are critical.

Agate Jars

Natural agate material is resistant to acids and chemicals, making agate jars suitable for milling and mixing sensitive materials. Agate jars are commonly used in pharmaceutical and other laboratory settings where the purity of ground materials are essential.

Tungsten Carbide Jars

Extremely hard and wear-resistant, tungsten carbide jars are ideal for processing hard and abrasive materials such as hard metals, minerals, and ceramics.

Polyurethane Jars

With their chemically inert and non-stick properties, polyurethane jars can be used for milling operations that involve samples that may corrode or react with other materials, such as strong acids or bases. However, due to the relatively lower hardness of polyurethane jars, they may not be suitable for high-impact grinding applications.

Alumina Jars

High-purity alumina jars are chemically resistant and have properties that can withstand high temperatures, which make them ideal for milling operations with heat-treatment methods. They are also often used for grinding hard substances like minerals and ceramics.

Zirconium Jars

With zirconia’s high durability and wear resistance, zirconium jars are widely used for applications that involve processing hard substances.

PTFE Jars

Polytetrafluoroethylene (PTFE) jars have unique properties that are generally favoured by researchers especially for chemical laboratory applications. Their highly resistant and non-reactive nature is ideal for milling processes that utilise chemically sensitive materials, acids, or other corrosive substances.

Where are grinding jars used for?

Pharmaceutical Industry

Grinding jars are commonly used in developing pharmaceutical products. These jars are typically employed in ball mills to prepare samples to achieve specific formulations. They may also be used for mixing and blending different components to ensure uniform distribution of ingredients.

Food Processing

Mills or grinders are used to create powders, pastes, or flours during the food processing and manufacturing processes. They also help refine sugar crystals and create consistent textures in various sweets.

Research and Development

Grinding jars help researchers produce finely ground powders or composite materials to achieve desired characteristics or obtain samples that can be used in further analyses.

Agricultural and Environmental Sciences

In certain processes, leaves, stems, seeds, or roots are crushed to extract compounds. Grinding jars provide a controlled environment for the collection and preparation of the samples for further analyses.

Metallurgy and Mining

Grinding jars play a crucial role in sample preparation and extraction of valuable minerals from ores. These jars can also be used in quality control processes to ensure the consistency and reliability of material properties.

How to choose the right jar size?

Size and Volume of the Material

Consider the amount and volume of material you need to process in a single batch. For high-volume processing requirements and larger sample materials, opt for a bigger capacity grinding jar.

Equipment Compatibility

Make sure that your milling equipment can accommodate the size and type of grinding jar you plan to use.

Material of the Samples

Take into account the hardness and abrasiveness of the samples you will be processing. Harder materials like ores and ceramics may need a more robust, wear-resistant jar material, which usually comes in larger sizes.

Space Constraints

Ensure that your laboratory or workspace can accommodate the grinding jar equipment. Ensure that the size of the jar does not hinder the operation or create safety or space-related challenges.

Frequency of Use

If you frequently use the equipment for milling processes, it may be practical to choose a jar with larger capacity to reduce the times required to load and unload the materials.

How to clean grinding jars?

- Clean the grinding jars regularly, especially if they are used for a variety of samples to prevent the accumulation of residues.

- Empty the grinding jar. Make sure there are no residues or remnants of the processed material by scrubbing the surfaces and crevices with a spatula or soft brush. Avoid using scouring pads or abrasive tools that can scratch or damage the jar’s surface.

- Soak the jar in the cleaning solution if necessary. Keep in mind to use a solution appropriate for the material of the jar. For example, you may have to use non-corrosive cleaners for metal or ceramic jars, and mild detergents for plastic or glass materials.

- Allow the jar to air dry completely. Avoid using towels or clothes that may leave lint or fibres.

- Store the grinding jar in a clean environment to prevent contamination before its next use.

What accessories can enhance the functionality of the jars?

Jar Lid and Seal

An airtight lid helps minimise exposure to external elements and prevent potential sample contamination. Some manufacturers offer grinding jars with their corresponding lids, which are particularly useful for applications that require a controlled environment.

Grinding Balls

Depending on the type of milling equipment, adding specific media such as stainless steel grinding balls can enhance the efficiency of the grinding process. Different sizes and materials of the grinding media are available for various applications, so make sure to consider these factors when choosing the proper accessory.

Liners and Coatings

Liners and coatings can be used to protect the jar’s interior from wear and contamination. These are especially beneficial when grinding abrasive or reactive materials.

How to safely handle grinding jars

Before Operations

- Before operating the equipment, familiarise yourself with the manufacturer’s instructions and guidelines. Always follow the recommended procedures and specifications to ensure the safety and efficiency of the process.

- Inspect the jar for any signs of damage, such as cracks or chips. Do not use damaged jars to avoid compromising safety and performance.

- Make sure that the grinding jar is securely attached to the milling machine. The attachment mechanism should be tight and stable.

- Choose appropriate grinding media based on the material being processed.

During Operations

- Do not overload the grinding jar. Follow the recommended load capacity guidelines to prevent excessive wear on the equipment and to ensure efficient grinding.

- Always wear personal protective equipment (PPE), especially when working with potentially harmful materials.

- Consider using cooling systems or allow the equipment to cool before each grinding session to prevent overheating.

After Operations

- Turn off the milling equipment before attempting to handle or remove the grinding jar.

- Follow proper cleaning procedures to prevent cross-contamination between samples.

- Store the grinding jar in a clean and safe environment.

Why you should choose high-quality jars

Less Maintenance

Grinding jars made of durable materials can withstand the rigours of grinding and milling processes, especially when working with abrasive materials. This durability ensures a longer lifespan, reducing the need for frequent replacements and maintenance.

Chemical Compatibility

Depending on the material of the jar, some are designed to be chemically resistant and compatible with a wide range of substances. This is particularly important when processing reactive or corrosive materials, as lower-quality jars may degrade or contaminate samples.

Manufacturer Support and Warranty

Reputable manufacturers offer warranties and reliable customer support in case of unexpected issues. This gives buyers confidence in the reliability and performance of the equipment.

FAQs:

How much does laboratory grinding jars cost?

The cost of grinding jars vary depending on the manufacturer, material, size, and integrated accessories such airtight lids, safety switches, as well as heating and cooling systems. Across International offers various grinding jars that range from A$ 249.00 to A$ 1,290.00 depending on the material.

Where to buy high quality jars?

You can purchase high-quality grinding jars from various suppliers, including scientific equipment distributors, laboratory supply companies, and manufacturers. Across International has a wide variety of grinding jars, accessories, and ball mill equipment that meet industry standards and cater to diverse laboratory applications.

Conclusion

Grinding jars are indispensable equipment used in laboratory settings across various industries. It’s essential to understand the differences in each jar material and consider the specific requirements of the milling operation to ensure optimal efficiency. Also knowing the proper procedures in handling and cleaning the equipment ensures the longevity of the tool and the overall success and safety of the operation.

Browse Our Cutting-Edge Selection

Across International offers various equipment for your laboratory needs. From ball mill equipment to fundamental ball mill accessories, we provide only the highest-quality laboratory solutions that cater to your specific requirements.

For more information about our products, reach out to us at 1300 118 228 or Info@AcrossInternational.com.au.