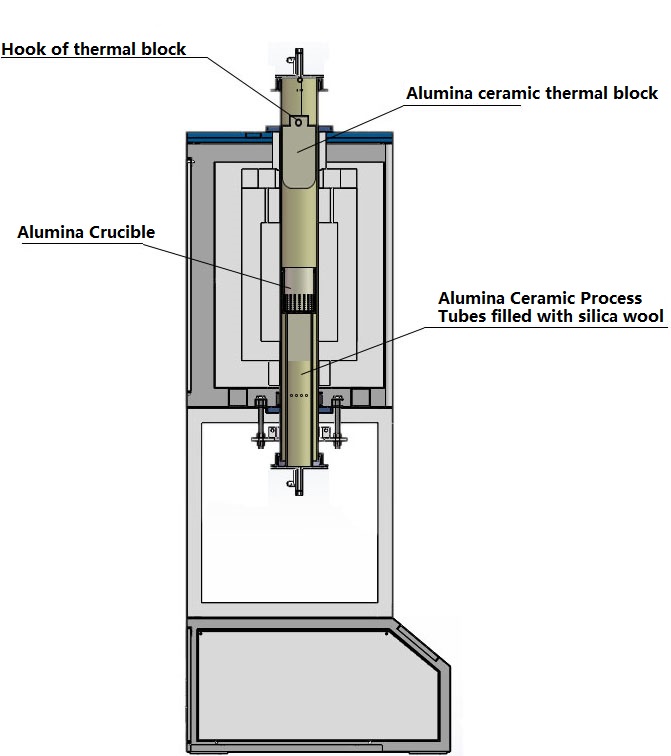

This VTF1500 series split tube furnace with fluid bed turns out perfect results each time you use it. Within you’ll find Silicon carbide (SiC)s for its heating elements. These are placed inside high-quality Mitsubishi alumina fiber insulation. The furnaces double-walled, steel, internal housing keeps heat from escaping to the surface. A Eurotherm 5 on-board process recipes (48 parameters per recipe) digital controller allows for precise temperature control, while its self-tuning PID controller provides optimized thermal processing consistently.

The controller has a built-in RS485 digital communications port with USB adaptor. This allows for remote control and monitoring directly from your PC. You can even export or save your test results. One very useful feature, with the furnace, you can perform multiple atmosphere processes in a single cycle.

This furnace is portable, lightweight, and has a small footprint. The chamber is easy to access. A built-in ammeter and dual voltmeters allow for easy monitoring and troubleshooting, while it’s type S thermocouple ensures its longevity. This unit comes with stainless steel vacuum sealing flanges with valves and a pressure meter. Safety features include overheat and power failure protection. This and all of our furnaces arrive at your door CE certified.

Features

- Compact, portable and lightweight design.

- Split furnace chamber for fast and easy tube access.

- Standard package includes set of stainless steel vacuum sealing flanges with valves and pressure meter.

- Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Multiple atmosphere processes in a single cycle are possible (ex: binder burn out in air and parts sintering under rough vacuum or inert gas environment.)

- Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- Long life type S thermocouple.

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

Warning! NEVER fill furnace with explosive gases, including Hydrogen, Carbon Monoxide and Methane.

.jpg)

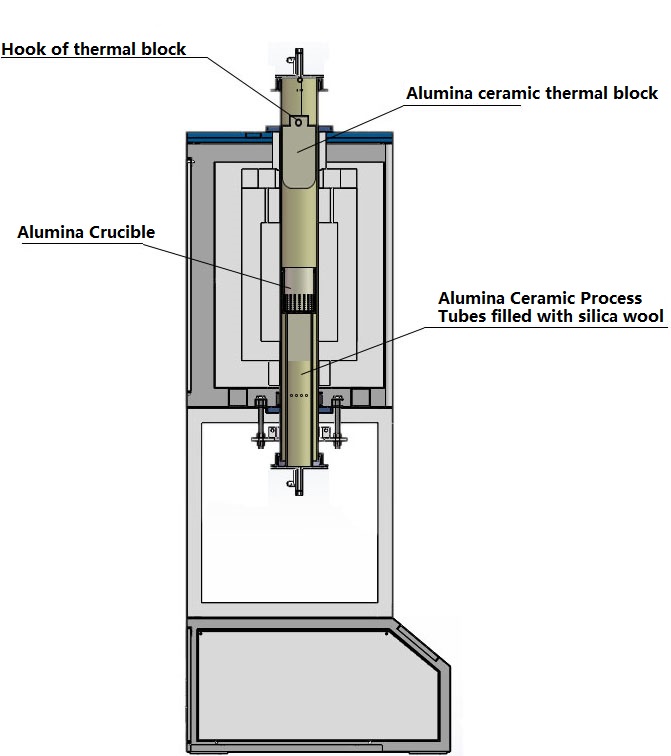

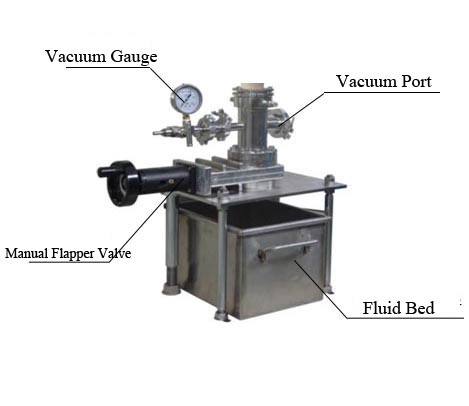

Fluid Bed

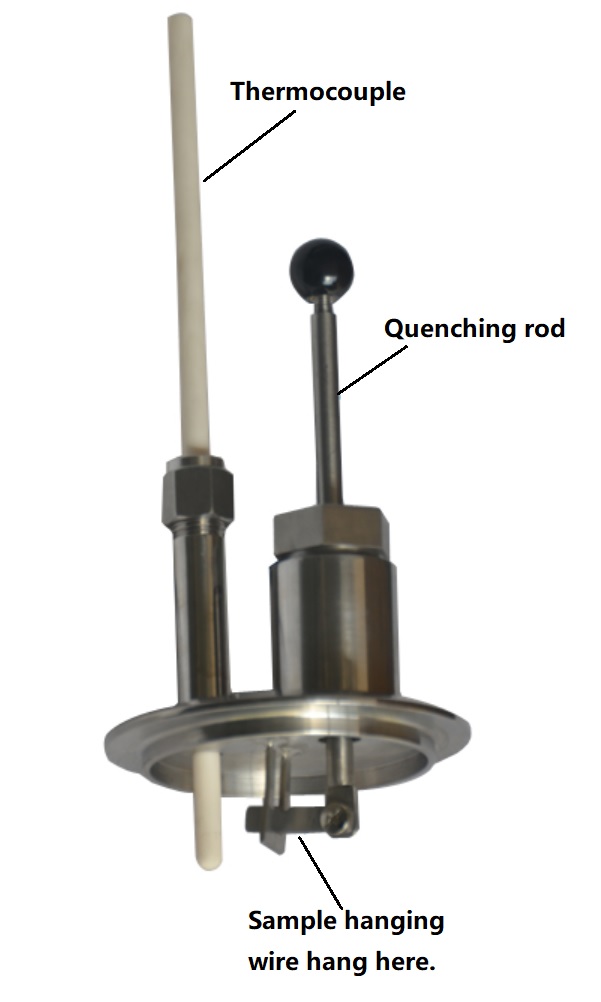

- A quartz rod with a hanging basket is located in the middle of the upper flange.

- The to-be-processed material is placed in the basket.

- A large manual flapper valve is installed between the bottom of the tube and the liquid cartridge.

- The quartz rod can be moved up and down and to quench the material in the basket into the quenching liquid box.

.jpg)