-

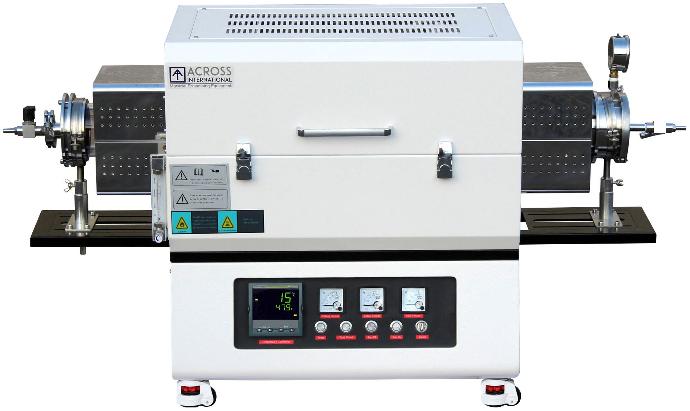

Tube Furnaces

-

Muffle Furnaces

-

Controlled Atmosphere

-

PE/CVD Furnace

-

Vacuum Furnace

-

Vertical Furnaces

-

Accessories

-

Vacuum Furnaces

-

Parts

-

High-Temperature Furnaces

Laboratory Furnaces

The tube furnace was first created in the early 20th century to manufacture pre-lightbulb ceramic filaments, used in glowers and Nernst lamps. Today, such furnaces are employed where precise temperatures are required, usually in a lab or manufacturing setting. Solid state chemists in find this device indispensable. It’s also used in manufacture. Coating, hardening, drying, aging samples, purification, brazing, annealing, and sintering sublimation are among it’s uses. So how does it work?

Samples are placed into its heated tube for certain purposes. Tube furnaces can have a horizontal or vertical orientation. Vertical tubes take up less space and provide faster heating. Samples are usually placed in a ceramic or metal boat, then shoved inside with a push rod. Any gases formed during the process pass through the tube and out a bubbler.

Desirable options include rapid thermal processing which allows for maximum heating and cooling, a gas processing capability, a rotating tube for coating uniformity and superior powder processing, and multi-zone heating--which allows for independent control of multiple temperature zones. Tube furnaces have a variety of uses including synthesizing or purifying inorganic compounds, drying, brazing, melting, material testing, gas processing, and much more.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Across International for Lab Equipment?

Choose Across International for your lab equipment needs, where the highest quality standards are paramount. Our products undergo rigorous testing to ensure reliability and performance.

We pride ourselves on exceptional customer support. We offer pre-sales consultations to help you find the right tools, as well as comprehensive after-sales service for ongoing assistance. Our dedicated technical support team is always ready to address queries, ensuring a seamless experience from purchase to application.

Shop Our Laboratory Equipment Range

Explore our wide selections ranging from basic tools to specialised instruments, catering to diverse fields and applications:

- High frequency lab induction heaters

- Laboratory furnaces

- Rotary evaporators

- Vertical furnaces

- Chillers and heaters

- Peristaltic pumps

- Analytical balances

- Laboratory freezers and refrigerators

- Laboratory distillation equipment and kit

- Ball Mills

- Homogenisers lab equipment

- Medical face masks and wipes

- Ovens

- Laboratory reactors

- Laboratory presses

- Vacuum pumps and accessories

Across International offers high-quality laboratory equipment, ensuring reliability and optimal performance for your everyday applications. Each product is designed to meet the highest standards, giving researchers confidence in their results.